Our activities are based on safe and responsible production and services that prioritize both environmental and human well-being.

Sustainability and Quality

Sustainability and quality are integrated into every stage of our operations.

Our Sustainability Priorities

Environment

- Actively working to reduce environmental impact.

- Prioritizing carbon emission reduction throughout the product lifecycle.

- Adhering to principles of a circular economy.

- Environmental Product Declarations (EPDs) developed.

- Application of various global sustainability systems.

- More information below.

Social Responsibility

- Sharing our experience and knowledge with students and field professionals.

- Ensuring the safety of our employees with health and accident insurance and providing support during significant life events. Read more here.

- Involving employees' families in various construction and safety-related activities and competitions.

- Contributing to diverse charitable initiatives.

Governance and Quality

- Operating in accordance with internal policies that foster a transparent and socially responsible work environment with the goal of preventing discrimination and corruption.

- Our processes are certified according to international standards for quality (ISO 9001:2015) and environmental management (ISO 14001:2015). Occupational health and safety processes are managed in accordance with ISO 45001:2018.

Safety is Our Core Value

In our factories, we prioritize the working conditions and safety of every employee. We conduct ongoing safety audits and assessments of our facilities and continually update our knowledge based on industry best practices.

Our processes adhere to the guidelines of the international ISO 45001 standard.

For further information about occupational safety activities in the UPB Group, click here.

We Know How to Reduce the Environmental Impact

We have created specific guidelines aimed to improve our environmental performance.

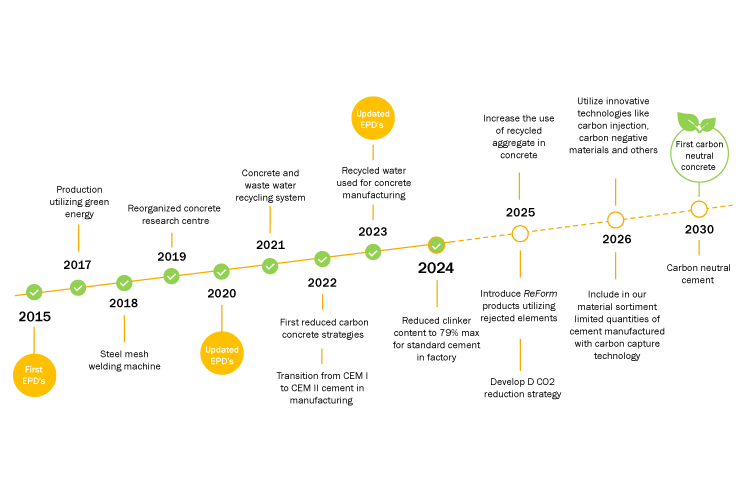

Some of our set goals we have already achieved, for example, shifting to green energy use, creating environmental product declarations (EPDs), reusing water in production, among others, all aimed to moving closer to our 2030 goal of producing carbon-neutral concrete.

Environmental Activities for Precast Production

Environmentally Friendly Factory and Equipment

- Zero waste production

- Wastewater purification with filter press technology

- Fresh concrete residue recycling equipment

- Water recirculation system

- Implementation of new, environmentally friendly equipment and equipment in factories

Improved Product Formulations

- 25% improvement in product environmental declarations

- Three different strategies for reducing CO2 emissions

- Implementation of the “One Click LCA program” for CO2 calculation and life cycle assessment

Reduced CO2 Emissions

- Efficient solutions implemented at the design stage

- Implementation of circular economy principles

- Environmentally friendly transportation planning

Assessing the Environmental Impact

Our latest environmental product declarations (EPDs) confirm that we have achieved 25% improvement in the environmental performance of concrete products. We assessed the entire product lifecycle – from raw material production, manufacturing, logistics and construction, till end-of-life considerations.

EPD products: beams and columns, floor slabs, hollow core slabs, wall elements, filigree decks and others.

EPD's for ready-mix concrete

Our ready-mixed concrete branch - Transportbetons MB - has become the first in the Baltic States to develop an Environmental Product Declaration (EPD) for its ready-mix concrete products.

This significant milestone aligns with our ambition to offer more environmentally friendly products for our customers throughout Latvia.

Product Certification

Our products are manufactured according to standards, and we regularly collaborate with independent auditors to assess compliance with CE and other product markings.

Compliance with quality standards is verified through issued manufacturing control certificates.

Supply Chain

The Quality, Health, Safety, and Environmental (QHSE) Management System is integrated into both the internal and external supply chains, from sales and design to product manufacturing, delivery and assembly.

The certificates of MB Betons Group are compiled here.