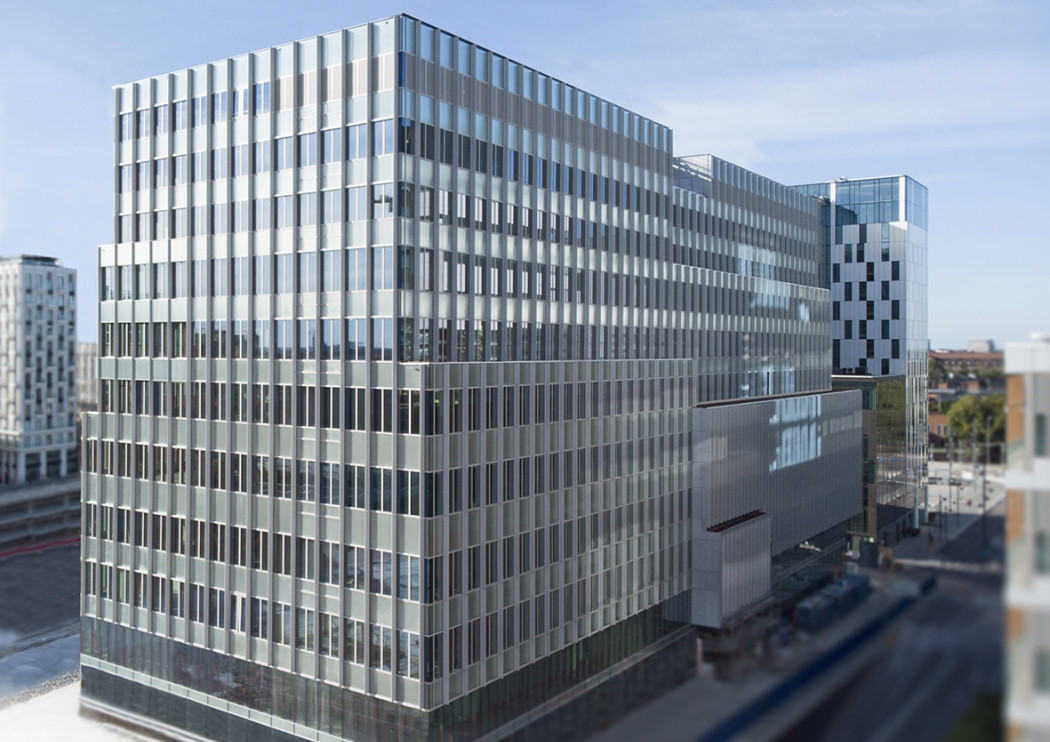

UPB carried out the engineering, production and assembly of the building frame and façade. MB Betons ensured the manufacturing of prefabricated concrete elements. In total it involved a 11 150 square metre glass façade made of 1213 façade elements, 1700 tonnes of steel structures and 4400 prefabricated concrete elements.

Several challenges were solved:

- There is a helicopter landing spot near the clinic so there were high requirements for sound insulation. The façade had to bear 50 decibels. UPB engineers found a way to do this.

- As it is a clinic there are high requirements regarding hygiene. To satisfy these requirements we used antibacterial glass with silver ions.

- UPB had to foresee a possibility to remove a large part of the façade in the case if any large equipment might be removed or installed in the hospital. To solve this our engineers designed large and heavy façade elements on both sides of the building. One such element is more than 18 square metres large (about the size of a medium living room), and had to be transported and installed with special building machinery. There are 17 elements in the building larger than 18 square metres.

- As an eye clinic and a building that was built according to Miljobyggnad requirements, there were tough requirements on the light transmission through the façade and we installed the façade with 2 different types of blinds – external blinds and internal blackouts; we have also foreseen an opportunity to attach one more blind for in the case if the tenant needs it. It was the architect’s requirement to hide the external blinds in some parts of the facades and this was achieved by hiding them under the special glass.

- The architect had an idea to make the building look more appealing by designing large vertical façade with a width of 350 mm and . It was slightly challenging to install the large lamelas and find a solution to avoid thermal bridges. As to the glass parts with a waterfall effect, UPB found a solution to satisfy the architect’s requirements.