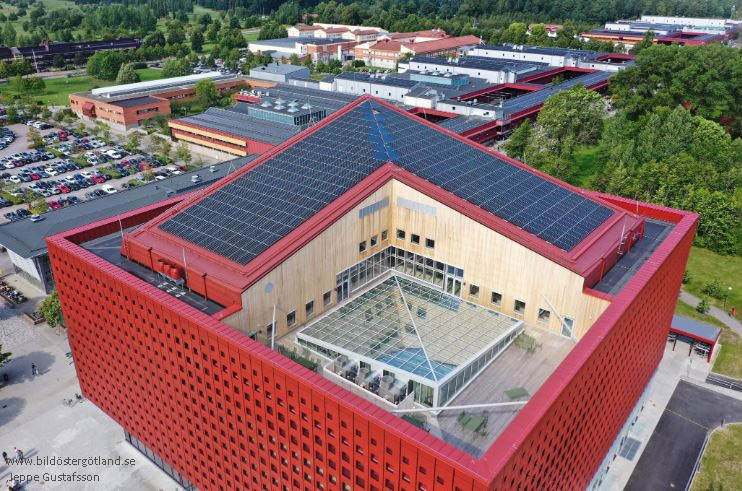

The student building stands out with its shape, color and size. Sustainability was also a very important factor and the project developer wanted a building with a gold certificate for the environmental building (Miljöbyggnad guld), which was also achieved.

In this project, we would like to highlight the assembly of adhesives and the elements of the grandstands with increased surface requirements in production and assembly. The grandstand elements were manufactured in specially made and unified steell molds, using concrete according to a specially developed recipe. Several elements had to be remanufactured to achieve the desired result. Working with adhesives was a pleasant change due to the smell and appearance of the wood. There were a lot of fasteners, but thanks to the experience and ingenuity of the assembly team, the usual tools were adapted so that the work could be performed smoothly and with high quality.

Throughout the process, there was excellent communication between the parties involved, which allowed to achieve the best results within the planned schedule.

Thanks to everyone involved for the work well done!